Company

Leading companies in Italy and Europe for the construction of measuring instruments.

CONTROL PROCESS, founded in 2001 in the province of Catania, is today one of the leading companies in Italy and Europe for the construction of pressure gauges and thermometers designed for different fields of application.

The company, synonymous with quality and high specialization, offers the international market an extremely complete range of products to meet the countless applications.

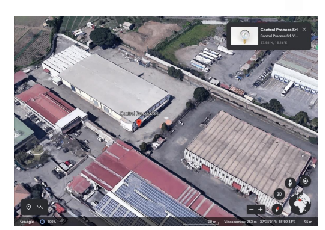

Operational Headquarters

Via Anzalone 22, 95024 Acireale

Tel +39 095 721 38 41

mail info@controlprocess.it

web site www.controlprocess.it

What are the objectives

The main objective of CONTROL PROCESS is to offer a superior quality standard for each product.

Since the beginning, the design, construction and sales guidelines are based on the belief that “all instruments must stand out for their stability and reliability as well as guarantee excellent performance”.

Quality

Customer satisfaction always comes first CONTROL PROCESS has always paid the utmost attention to satisfying the requests of its Customers;

moreover, to start a process of continuous improvement, both of the product and the service to the Customer, and of the production process, the Management has introduced Quality Control for several years, which subsequently developed into a Quality Assurance system. The Quality Assurance System assigns rules of conduct, responsibility and objectives for the quality of the product and service, at every operational level, in order to always guarantee compliance with the technical / quality requirements of

its products.

The fundamental points of the quality policy

✓ Provide competitive, reliable and safe products.

✓ Ability and flexibility to meet customer needs.

✓ Careful assistance service in choosing the product and after-sales.

✓ Fast delivery times and respect for them.

The Quality Assurance System requires a systematic data collection, to periodically evaluate theachievement of the objectives imposed by the Quality Policy, according to a strategy of continuous improvement.

✓ Lean, efficient organization, with precise levels of competence and responsibility.

✓ Continuous training and updating programs for all operational staff.

Quality in design and development

✓ Computer-aided design, developed according to precise work plans to control the development phases of each new product.

✓ Careful analysis of the information and experiences acquired on the market, of customer requests, to develop each new product in line with market trends.

✓ Execution of meticulous tests during the fine-tuning of the prototypes.

Suppliers and production

Careful selection of strategic suppliers, who work in close collaboration with the technicians of CONTROL PROCESS, according to precise quality requirements.

✓ Modern production technologies to ensure maximum precision in processing, with maximum business efficiency.

✓ Planned and controlled production using modern computer systems, to know in real time the progress of orders.

✓ Checks and tests established at each stage of the process, considered fundamental to ensure compliance with all the technical / quality requirements of each product.